Equipmake has revealed fuller details of its battery-electric repower offer for coach models. It comes as the first such example, a Van Hool T917 tri-axle for Westway Coaches, made its public debut.

That vehicle has been with the supplier since February. It is expected to return to Westway in late summer after completion and testing, and has five 109kW/h NMC battery packs to give a total energy capacity of 545kW/h. All batteries and control units are behind the rear bogie and thus do not impact underfloor luggage space.

Also behind the tag axle is the motor package. It uses a pair of Equipmake’s HTM-3500 compact units mated together. That arrangement gives a combined 7,000Nm of torque and 800kW of power.

Equipmake can fit six or seven battery packs if luggage capacity is of lesser importance. That would give 654kW/h or 763kW/h of energy storage respectively, although Managing Director Ian Foley stresses that such installations are possible only on a three-axle coach. However, Equipmake believes that 545kW/h can be done on two axles, albeit with a constraint on luggage capacity.

Tri-axle arrangement ideal for battery-electric coach repower

The Westway Van Hool will deliver a range of up to 220 miles, Equipmake says. No impact on the cabin comes with the conversion and the supplier has not had to uprate any axles on the coach, although Mr Foley expects that its unladen weight will increase by around 1,000kg from diesel to battery-electric.

Placing equipment on the roof forms no part of Equipmake’s coach repower plans owing to questions over whether body structures would support such additions, although Head of Sales and Marketing Jasmine Bishop says that chassis strengthening on future conversions will be added if required. That has not been the case with the T917.

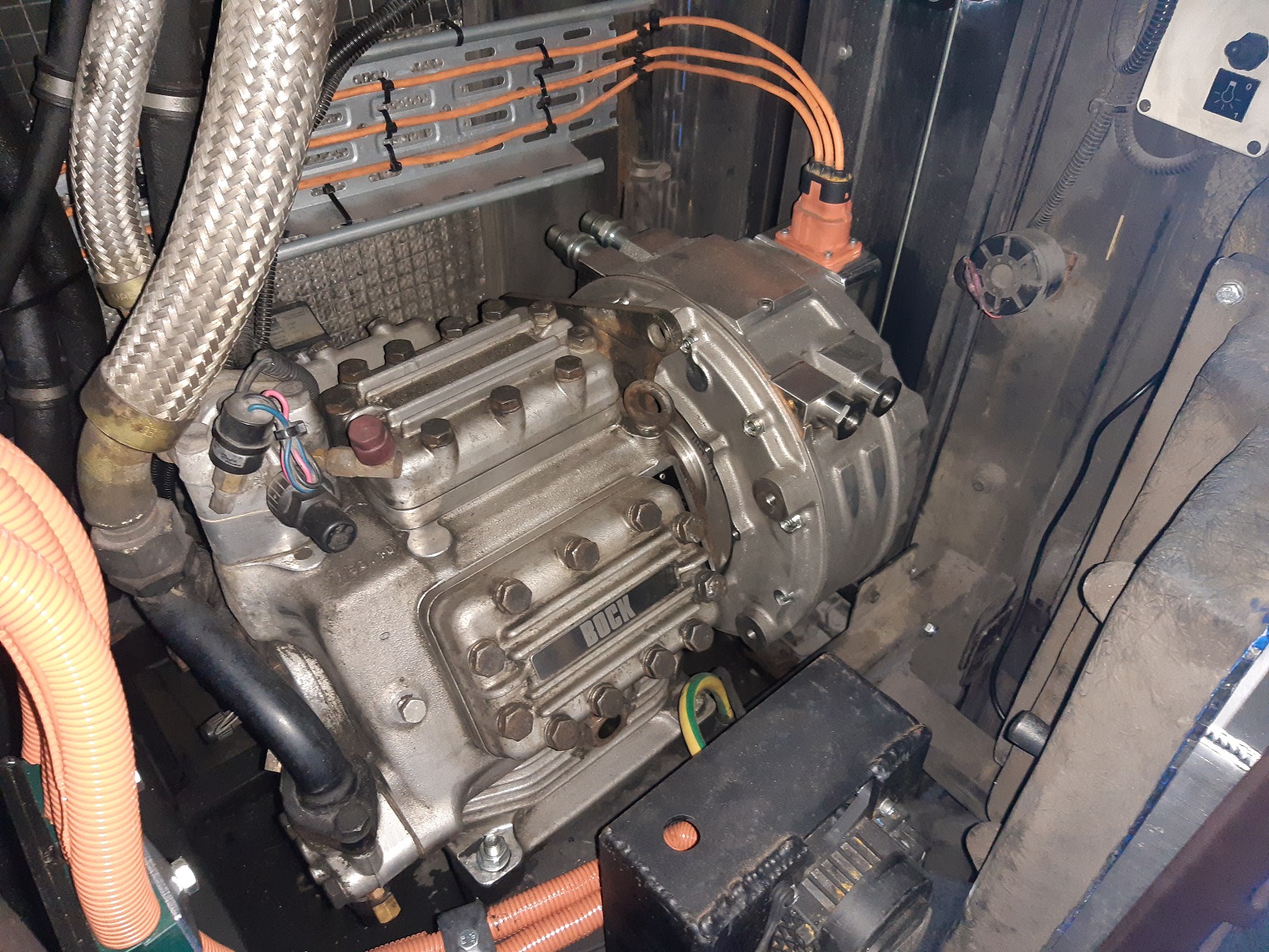

A lot of thought has gone into the heating and air-conditioning provision for converted coaches, Ms Bishop continues. The T917 has a large air-conditioning compressor that was previously belt-driven by the engine. To replace the belt drive, Equipmake has fitted a small electric motor direct to the compressor.

For heating, Equipmake will fit a heat pump, partly to harness waste energy from the batteries and also to deliver maximum efficiency. Mr Foley anticipates further work in the future to bring heating and cooling into the same optimised unit, possibly via modification of the OEM air-conditioning equipment. The air compressor and power steering pump are driven by a single motor.

‘Government needs to oversee zero-emission infrastructure network’

Charging is DC via a CCS2 connector. Ms Bishop says that the vehicle-mounted receptacle can be placed to suit the operator. Input power is currently limited to 150kW but Mr Foley is confident that more will eventually be possible.

On the potential for repowered coaches to utilise pantograph-based opportunity charging, he adds that such work will be possible. Vehicle-mounted equipment for that purpose is a relatively easy fit, although the necessary infrastructure would be an important consideration for the operator.

Mr Foley believes that a bigger question surrounds how UK PLC will ensure sufficient power and public infrastructure is in place to support a widespread move to zero-emission for heavy vehicles, regardless of how electricity or hydrogen is taken aboard.

“It needs government oversight because of the scale of what is required. Bus is easier, because buses follow fixed routes. Coaches go everywhere, and more certainty over infrastructure is needed.”

Scope for battery-electric coach repower attracting interest

Equipmake has already seen interest in repower of other coach models. The battery-electric driveline’s installation on the Van Hool is well packaged and it would be straightforward to introduce the same to other tri-axles, the supplier says. Two-axle coaches are more challenging because of gross and axle weight limitations, but Equipmake is keen to examine them.

“The pipeline is hot on coach repower at the moment,” says Ms Bishop. That represents a major change of previous fortunes, and she gives credit to the agreement with Westway. “David West coming aboard gives us great credibility on our coach programme. Before, there was a lot of pushback from operators, but we’ve seen a big change since.”

While the Westway T917 majors on battery capacity, there are positives for both maximising onboard storage and customising it to suit lower-mileage applications such as home-to-school work, Equipmake believes.

Lower battery capacities to suit home-to-school applications?

Mr Foley points out that more batteries give scope for more miles. With electricity prices now dropping, there lies potential to maximise the running cost benefit.

At the opposite end of the scale, use of either one or two of the 109kW/h battery packs in repower would suit home-to-school applications. Equipmake has done the sums there, and believes that with a modest amount of subsidy such an approach could stack up financially.

“Based on a nominal 100kW/h of battery capacity, the cost to run a coach is incredibly low,” says Ms Bishop. “The attractive calculations for a home-to-school application are all down to the lower battery size, because the cost in a repower lies with the energy storage.”

The Westway Van Hool is proving that battery-electric repower for coach is an achievable option in the right operational circumstances, while an approach to smaller battery installations for home-to-school use has already been picked up by one operator.

With government funding to support more conversions, the supplier believes that demand could grow rapidly. It promises a two-week conversion period once a model’s repower process has been productionised.