Whether it’s the crucial legal responsibilities of compliance or the desire to refurbish in order to repurpose or modernise, there is so much for every coach and bus operator to consider when it comes to the refurbishment and maintenance of vehicles.

With the help of some of the most respected suppliers in the trade, we look at areas including digital compliance systems, maintenance pits, the benefits of modernising workshop equipment, mobile column lifts, and the advantages of buying British.

Digital compliance reporting

Keeping on top of vehicle maintenance and doing so in a way that meets legislation is an important considerations for every operator.

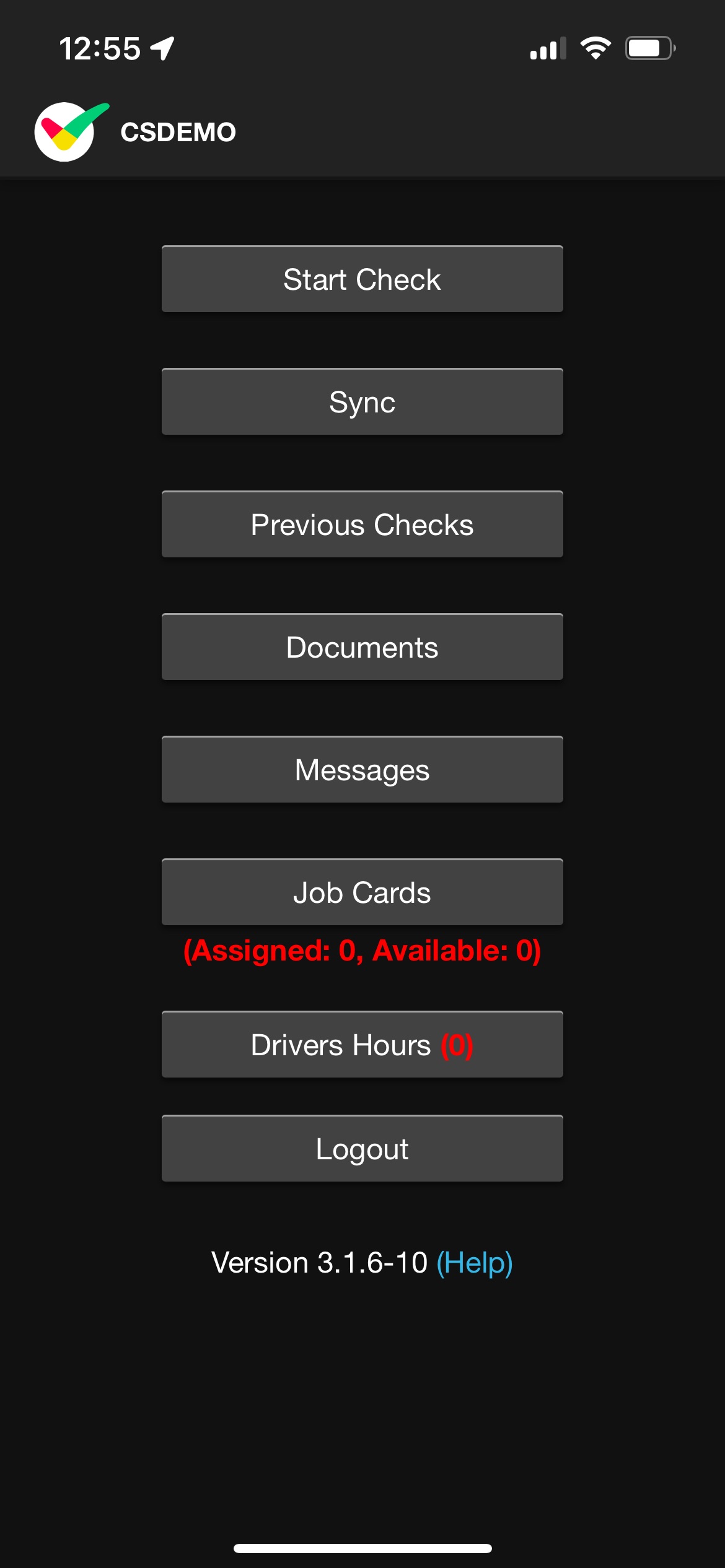

Digital compliance reporting systems such as CheckedSafe can save time in the workshop, cut down on paperwork in the office, and help ensure you meet obligations with the DVSA and Traffic Commissioner.

Using the app on their phones, drivers can complete their daily walk-round with ease, with all checks separated into clear categories.

These can be customised to suit the needs of the business and the reports can be stored offline if the signal is poor.

All the data is then available to office staff via a full back-office software package which can provide detailed maintenance reports.

Being DVSA-accredited software, it can also be used to stay compliant with the Earned Recognition programme.

CheckedSafe co-founder and Director Gary Hawthorne adds: “Staying on top of vehicle maintenance and daily walk-round checks isn’t just best practice; it’s critical.

“With CheckedSafe, you get a seamless, digital solution that ensures compliance, improves safety, and keeps your fleet running efficiently and effortlessly.”

Inspection pits

With operators always looking to cut costs, bringing vehicle maintenance in-house is one of the ways a coach or bus business can try to expand those slim profit margins.

For those wishing to do this, having safe and efficient inspection pits installed at the depot is one of the first and most basic requirements.

With more than 35 years’ experience in manufacturing maintenance pits, Premier Pits offers a diverse selection of products, including those for inspection, maintenance, ATF and rail.

Its offering of accessories includes under-chassis wash pits and ramps. It is also the UK’s official supplier of BrakeMate, which simplifies the brake disc replacement process by eliminating the need for heavy lifting.

This solution offers a quick and easy way to protect staff from accidents in the workshop

Premier Pits can also customise options to meet the requirements of the customer. The “online pit builder” allows you to visualise the equipment required and therefore maximise efficiency and safety.

Among the chief safety products on offer is the Premier “hinged cover” — a pit fall restraint to protect staff from falls while maximising the working space.

Premier Pits Managing Director Mel Burrell says: “There is no requirement for a storage cassette, meaning that a pit of any length can be covered with minimal working space lost.

“This solution offers a quick and easy way to protect staff from accidents in the workshop.”

Modernising equipment

While upgrading your workshop equipment could be seen as furthering the “throwaway culture” and not aiding sustainability, workshop lifting and testing supplier Totalkare believes this practice can in fact be eco-friendly.

Pavan Jheeta, Totalkare Marketing Executive, says: “We’ve come a long way with the tech behind modern testing equipment — and a long way as an industry towards a focus on greener practices.

“That means every piece of new kit that comes from a respectable manufacturer is being designed with the environment in mind. They’re leaner and more efficient. They’re built to minimise waste — and to perform at their best with the smallest amount of energy use.”

The business argues that these improvements in efficiencies add up across your workshop and you could see a dramatic reduction in both the energy you use and your bills.

That aside, Totalkare notes that savings in fuel could follow. “With the best testing equipment, you’re getting the most accurate results and data about your vehicles,” says Pavan.

“You’ll be able to keep your vehicles in the best condition and get the earliest warnings about potential issues, so you can make sure your vehicles are as efficient as they can be.”

Keeping it local

In recent years, many major component manufacturers have restructured their operations, reducing local UK manufacturing and assistance in favour of importing products and receiving remote customer support.

This change may not be immediately noticeable to operators but can become a factor when support is required, potentially affecting response times and operations.

However, companies like Passenger Lift Solutions (PLS) are highlighting the advantages of equipment that is designed, manufactured, and supported in the UK.

Morgan Clissett, After Sales Director at PLS, says: “When vehicle manufacturers and operators choose PLS, they invest in local expertise and direct support. Our lifts are designed, built, and supported right here in the UK. This allows for faster delivery, easier access to parts, and comprehensive aftercare.”

A lack of understanding of local requirements and preferences is also an issue seen by PLS. Morgan adds: “We’re seeing providers of equipment who want success in the UK market but have a fundamental lack of understanding of the unique needs of operators.

“For passenger lifts, this means equipment designed only for occasional use and not up to the stresses of UK social care and SEND transport.”

Mobile column lifts

Safety is paramount in commercial vehicle workshops, particularly when maintaining and repairing large vehicles such as coaches and buses.

Outdated lifting equipment can present several risks, including instability, trip hazards, and mechanical failures that jeopardise technician safety.

Stertil-Koni’s mobile column lifts have advanced safety features designed to ensure a secure and efficient working environment.

The mobile column lifts are available in both wireless and cabled configurations, each offering unique advantages for enhancing workshop safety.

The wireless models eliminate the trip hazards associated with cables, giving technicians full access around the vehicle without obstruction.

In contrast, the cabled versions provide a robust lifting solution, with optional heavy-duty interconnection cables that protect against damage.

Available in lifting capacities of 6.5, 7.5, 8.5, 10.0, 13.0, and 17.5 tonnes per column, the Stertil-Koni lifts come with a synchronisation system that helps ensure smooth lifting and lowering, automatically compensating for height differences as small as 15mm.

This is designed such that, even in cases of uneven load distribution, the lift operates safely and efficiently, reducing the risk of instability.