With a wealth of compressor system knowledge, Imperial Engineering is pleased to support operators with technical advice and guidance on maximising service life

Alternative fuel buses are here to stay as operators in city centres, such as those in London’s recently-introduced Ultra Low Emissions Zone, strive to meet increasingly stringent environmental controls.

This has led to several bus companies running alternative fuel vehicles in their fleets, as well as trialling various powertrain options such as full electric, hydrogen and hybrid.

Out of these, hybrid buses have already become a familiar sight in city centres, thanks to two manufacturers introducing double-deck hybrid buses five years ago, which have been in service ever since.

While a conventional diesel and a hybrid bus might look similar, they can be fundamentally different when it comes to producing compressed air, required for air braking, pneumatic suspension and clutch systems.

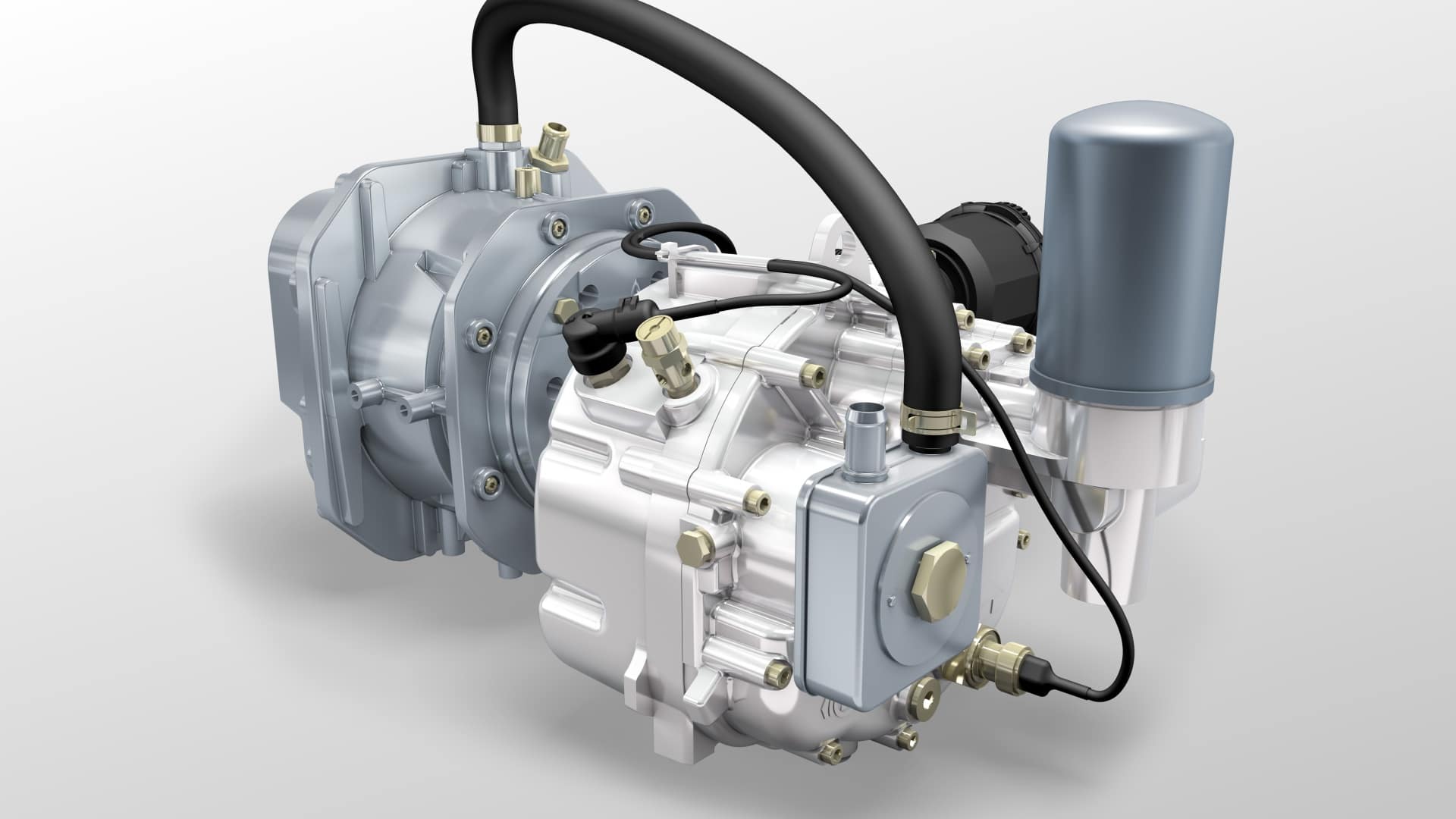

While diesel-powered buses use engine-driven compressors, some hybrids employ standalone electrically-driven compressors to supply a constant and stable compressed air supply. Originally developed for the rail industry, two hybrid bus manufacturers use electric compressors. Although sourced from different suppliers, they utilise very similar technologies.

Because diesel-driven compressors are attached to the engine and lubricated by the engine’s oil circuit, they require minimal maintenance and are designed to provide an average service life of five years, subject to factors such as the duty cycle and operating conditions.

When a new conventional compressor is required, the replacement cost is around £500. In comparison, standalone electrically-driven compressors have their own dedicated lubrication system, featuring special compressor oil and filters. These can cost up to 10 times more than their conventional counterparts to replace.

As a result, maximising the service life of electric compressors has become an important issue for operators.

Investigations carried out by Imperial Engineering have found that major contributors to component failure are excessive oil carry, resulting in leaks and dirt ingress into the compressor’s drive motor. This causes bearing failure, which leads to the compressor running very hot and ultimately failing.

To address this problem, Imperial Engineering recommends that operators inspect and service electric compressors on a regular basis, in line with manufacturer guidelines.

For example, Knorr-Bremse screw-type compressors (pictured) require servicing every 1,500 hours, while many are only being serviced annually and may have been running for 4,000 hours in the same year, covering around 90,000km during the same period.

- For further information call 01992 634255 or email enquiries@imperialengineering.co.uk