Yutong battery-electric single-deck buses have garnered significant market share in England, Scotland and Wales. The E10 and E12 range counts big groups, independents and municipal operators among its customers, and supplier Pelican Bus and Coach has significantly expanded its facilities and headcount to support those growing fleets.

“We are making a lot of investment to enable us to handle more vehicles on the coach and bus side,” says Pelican Managing Director Richard Crump. “Going forward, we expect the business to shape itself as one that delivers a significant number of new coaches and buses per year.” Key to work with battery-electric buses was the recent appointment of Mick Campbell as Customer Project Manager. He works alongside Head of Yutong Bus UK Ian Downie.

By the end of 2021, Pelican will have taken orders for almost 200 zero-emission vehicles since its first demonstrator arrived in 2016. It will deliver 113 in the final four months of this year. Talks with other customers are ongoing and Pelican remains committed to bringing a battery-electric Yutong double-decker to the UK, illustrating why work is being done now to prepare for the future.

In addition to its headquarters building and coach and bus showroom in Castleford, the dealership has a further premises that is heavily involved with completion and preparation work on buses after they arrive from China thanks to Pelican being an approved KD facility for Yutong. That location also provides extensive parking for vehicles awaiting entry to that process, and for stock coaches.

Yutong and Pelican collaboration on growing electric buses volumes

As a backdrop to that, work has also been underway at Yutong’s factory in China to ensure that the battery-electric product offered in the UK keeps pace with any diversification of market demand.

Development being undertaken by the manufacturer on the E10 and E12 for the UK centres on two areas.

One relates to the buses’ charging options, which are to grow in both scope and speed.

The other majors on the Yutong Electrical Safety Standard (YESS) for battery-electric vehicles, which the manufacturer says is “world leading” in its application.

Charging options: ‘Super-fast’ and opportunity to be introduced

Yutong battery-electric products for the UK all have DC charging. AC has never been an option, despite some early enquiries for it. The DC-only approach has not been wavered from because Pelican believes that safety and futureproofing benefits are to be had from sticking to it, says Ian.

Charging has thus far been undertaken using a single socket on each vehicle. However, Yutong can now fit twin plug-in points, with one on each side of the bus. When those are combined with an enhanced battery management system, each can simultaneously be connected to separate 120kW inputs. That combined 240kW allows what Ian says is “super-fast charging.” It gives potential for even a heavily depleted bus to be fully replenished in well under two hours.

Perhaps the biggest ticket in respect to charging the E10 and E12 is the introduction of scope for an opportunity connection. When specified, it will utilise vehicle-mounted rails and a gantry pantograph that can deliver up to 300kW. Such vehicles will come with 350kW/h of battery capacity, which represents a removal of two packs from the standard 422kW/h set-up.

When those figures are considered, Ian believes that an opportunity charging equipped Yutong bus is likely to need connection to the pantograph only once or twice per day, with those top-ups effectively acting as planned range extensions.

Opportunity charging will not be necessary for most buyers, although its coming has been market-driven, he adds. It has no impact on the eight-year battery warranty period.

“Addition of opportunity charging is in response to customer demand to explore how we can introduce the concept to the UK,” Ian continues.

“Yutong already builds battery-electric buses with opportunity charging for other markets, so this is not new technology. It was developed as part of Yutong’s work on autonomous vehicles. We are already speaking to potential buyers about it.”

YESS to be standard on UK market Yutong electric buses

YESS is a flagship workstream for Yutong. It has a variety of elements, with protection of the batteries from all potential damage and removal of any risk of a battery fire central to the theory behind it.

YESS will be fitted as standard to all buses ordered going forwards. The first to come here with the full suite of YESS aspects are six for Transport for Wales. They will be put to work on the TrawsCymru network in North Wales with a yet to be announced operator.

Those buses are also the first Yutongs to have rear-view cameras from Journeo in place of mirrors. Such cameras are now an option across the Yutong battery-electric bus range; when specified, they will be installed at Castleford as part of the vehicle completion work.

Nitrogen generator forms part of YESS

Principal parts of YESS are placing the batteries out of harm’s way; protecting them from damage should the bus be involved in a heavy collision by using robust covers; protecting them from the risk of a short circuit; and preventing a fire from occurring.

For the latter, YESS includes the fitment of a nitrogen generator that floods the batteries with the inert gas. Also part of YESS is 24/7 real time battery monitoring.

On the protection aspect, Ian suggests that Yutong’s decision to place batteries at the rear and on the roof makes fitting robust protective coverings to them simpler than if they were in other locations.

“YESS will be standard on battery-electric Yutong vehicles in the UK, including the TCe12 coach. It demonstrates the manufacturer’s core principle of safety, something that we share. YESS is something that not only meets safety requirements, but comfortably surpasses them,” he says.

Pelican is also keeping a close eye on the airside bus market. While demand there was hit by the collapse of air travel, the dealership has delivered a battery-electric ABe13 to Newcastle International Airport. That further demonstrates its focus on reaching a “significant” vehicle per year target – something that Pelican is confident that it will achieve sooner rather than later.

Before and after: Completing a bus at Castleford

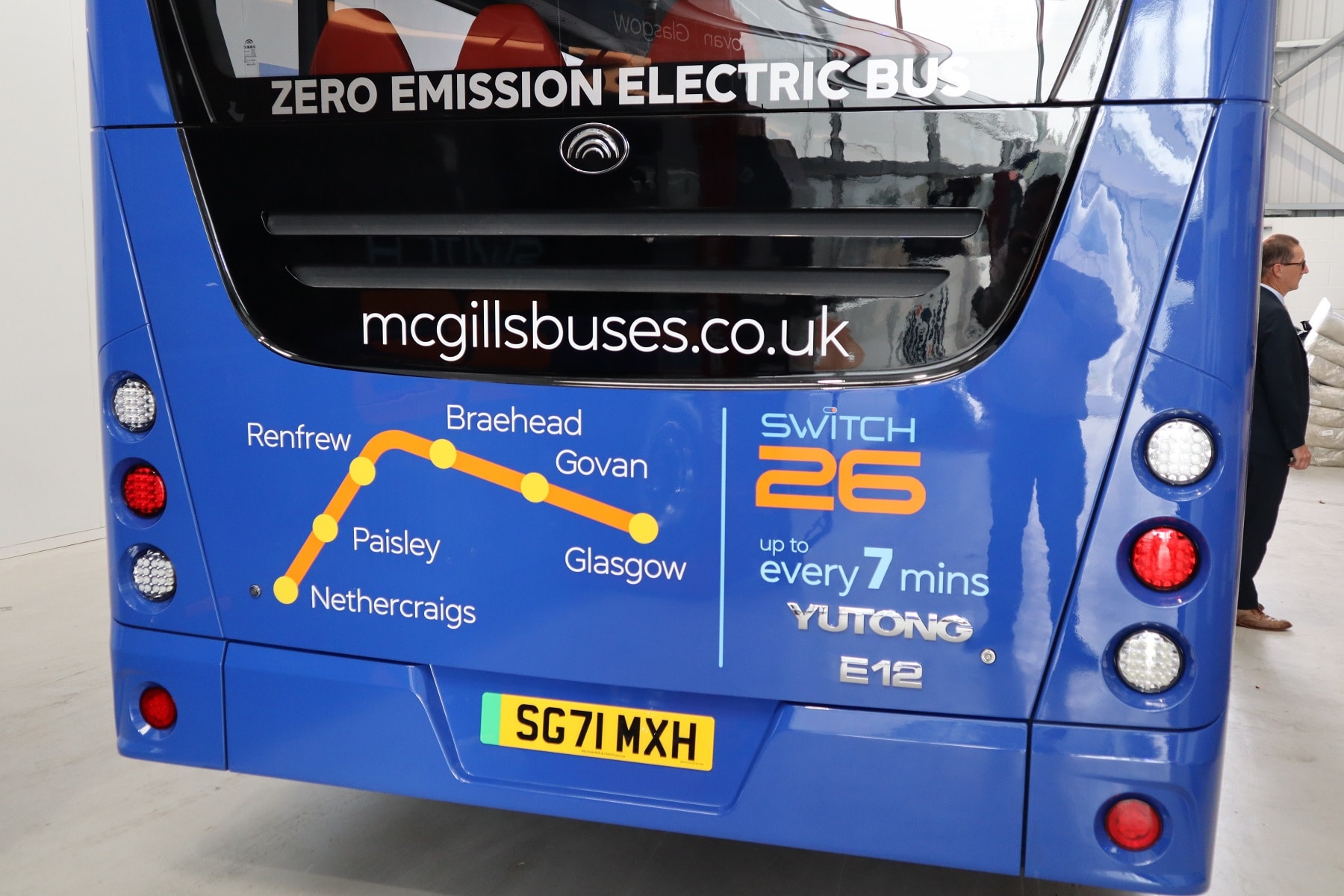

In early September, work was underway at Pelican to complete 21 Yutong E12s for McGill’s Buses. A further 33 were to start arriving the following week.

Such is the extent of the fit-out undertaken at Castleford before delivery that the first buses were able to enter service with McGill’s the day after arrival in Scotland. It takes around a week for all tasks to be completed at the dealership, which is impressive given the scale of work that is carried out.

routeone was able to take a ‘before and after’ look at different E12s from the first batch for McGill’s. They had arrived with little present internally, although wiring for items such as USB charging points, CCTV and others is installed at the factory.

Tip-up seats in the wheelchair user and buggy areas are similarly fitted, as is the position over the offside front wheel. Other seats, being from Esteban, are installed by Pelican, as are handrails that Yutong supplies with the bus. Pelican additionally fits a 24v booster socket below the cab floor, while suppliers attend to third-party aspects, including destination displays, CCTV and vinyls.

The dealership also commissions the batteries and performs a pre-delivery inspection. Buses move from Southampton to Yorkshire, and thence to Scotland, under their own power. They arrive in Renfrewshire after the 240-mile journey from Yorkshire with around a 35% state of charge remaining, says Ian.

Delivery of the two batches, plus a further bus that arrived ahead of them, will see Pelican come good on its promise to have all 55 E12s in service with McGill’s before the COP26 climate change conference gets underway in Glasgow on 1 November.