Volvo has launched the BZR Electric platform to fulfil battery-electric requirements for high-floor coach and low-entry interurban bus deployment.

Described as a basis for “several new products” by Volvo Buses President Anna Westerberg, the BZR Electric complements the established BZL battery-electric low-floor bus range. Ms Westerberg adds that the BZR represents “a product and a complete offer that will be a long-term solution for customers worldwide,” including right-hand drive applications.

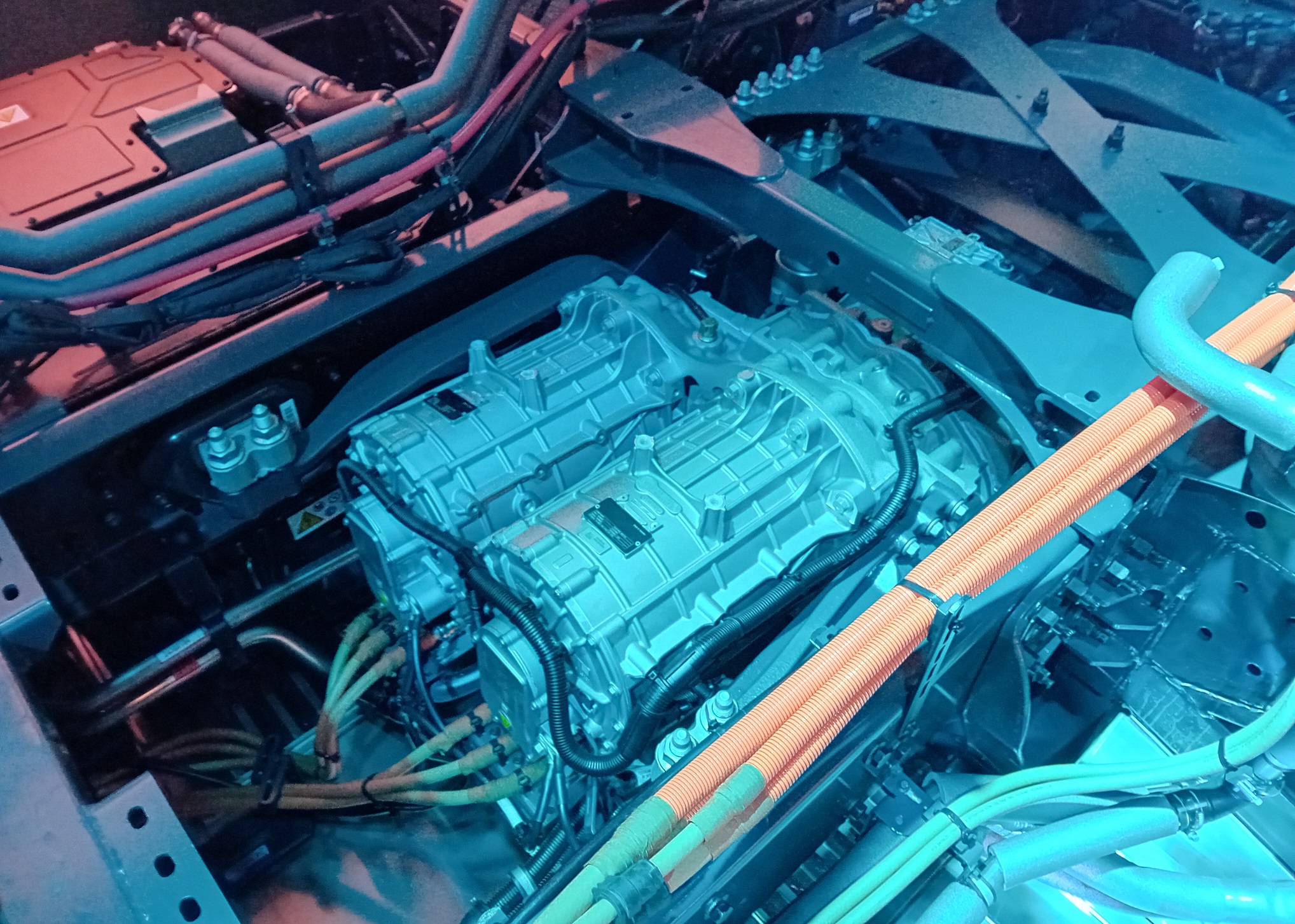

The newcomer will come in two- and three-axle layout and with various battery capacities and configurations. It leverages Volvo Group’s electromobility approach of sharing as much technology as possible across sectors, including common electrical architecture.

Major units will thus be manufactured in larger volumes for economies of scale. The 200kW motor in the BZR Electric is the same as in the BZL and 7900 Electric, while the batteries are already used in the FH Electric truck.

The base chassis used in the BZR is adapted from the diesel B8 range. Volvo encourages potential buyers to consider the two platforms as similar in application; the B8 line-up includes the B8RLE low-entry bus underframe and the B8R coach chassis, and the BZR will satisfy both of those use cases in battery-electric.

Volvo Buses Product Director Coach Jonas Törnblom notes that the BZR extends the OEM’s zero-emission capability “beyond the city.” He adds that the BZR will be taken further in the future, and the manufacturer is already talking about possible introduction of hydrogen fuel cell and hydrogen combustion power later.

Mr Törnblom says that the BZR has been designed with ease of component access in mind. Each modular battery is of 90kWh capacity and weighs 535kg. Between four and six can be installed to allow a maximum storage of 450kWh on two axles and 540kWh on three, but Volvo expects to up the three-axle limit to eight batteries and 720kWh later.

A T-drive layout is used, with drive taken centrally into a Volvo axle. Either one or two motors will be fitted, depending on application. The same two-speed automated manual gearbox as the BZL and 7900 Electric is included. The FH Electric truck uses a 12-speed I-Shift, but that was seen as overkill in a passenger application.

For coach and tri-axle usage of the BZR, Volvo expects that two motors will be installed. Control of those will be clever, says Product Director Fredrik Björn; they will be independent of each other, and at times of low power usage it will be possible to engage one and idle the other.

Central mounting of the motor(s) reflects the BZR’s varied applications in enabling various drive axle ratios. Use of a conventional layout and not hub motors also minimises unsprung mass, which Mr Björn says is beneficial for ride quality.

On weight of a B8 against a like-for-like BZR Electric, the latter will be heavier. However, Mr Björn observes that there is scope for greater flexibility with axle loadings with the BZR through the location of up to three battery packs at the front of the chassis. Because of that, it is likely that overall passenger capacity will be consistent.

Flexibility with battery siting also benefits coach applications. Volvo says that bodybuilders will have some scope to locate the 90kWh packs to best suit the maximisation of underfloor luggage space.

No in-depth analysis of energy consumption has yet been carried out by Volvo, but it believes that like-for-like, the BZR will have an edge over the BZL thanks to a revised cooling system.

On bodybuilders for the BZR, Volvo is tight-lipped. In addition to a development low-entry chassis, it already has one underframe at a partner in Latin America and three more will follow to body manufacturers this year. Production of the BZR will begin in 2025, with right-hand drive examples following relatively quickly, the manufacturer has said.

Volvo Buses UK and Ireland Managing Director Domenico Bondi will not be drawn on interest here so far, although he underlines a belief that widespread adoption of zero-emission in the UK coach market will likely hinge on financial support from governments.

On charging, the BZR Electric will accept up to 250kW via a single CCS2 plug-in, although Volvo is investigating whether two such connections could be used concurrently, says Mr Björn. The model will also take up to 450kW via inverted pantograph where required.

More information on Volvo’s approach to electromobility and zero-emission in the passenger market will follow in the April print edition of routeone, published on 10 April.