Welcome back to Switched On, a series of articles that we are writing to help operators to understand the best ways to drive down the lifetime costs of electric coach and bus operations.

In our first article, we set out the key drivers of total cost of ownership (TCO). Today, we are focusing on battery degradation.

This article is based on our experience supporting over 1,000 battery-electric vehicles to date and repurposing end-of-life EV batteries in new applications.

Thinking about the full lifecycle of a battery is key to minimising TCO. This article sets out how and why. As always, if you have any questions, do get in touch.

Steven Meersman, Co-Founder and Director, Zenobē

Battery degradation: What is it, and how can risk be managed?

Battery degradation is the effect where a battery’s energy storage capacity reduces over time, eventually rendering it unable to provide enough power for the operational mileage requirements of coach and bus operators.

The need to replace such a high-cost part of a bus is a risk not often faced when operating diesel vehicles, but it is a near certain requirement for electric. By managing this risk upfront, operators can avoid adverse impacts on both their operations, and their finances.

This article will give an understanding of degradation, the factors that affect it, the strategies to minimise it, and its implications on electric TCO.

Understanding battery degradation

The basics

Charging and discharging a battery is a chemical process that causes physical changes to the battery. Consequently, over time and with use, the total amount of energy that the battery can store will decrease, a phenomenon known as degradation. Different battery chemistries offer varying features, including differing rates of degradation.

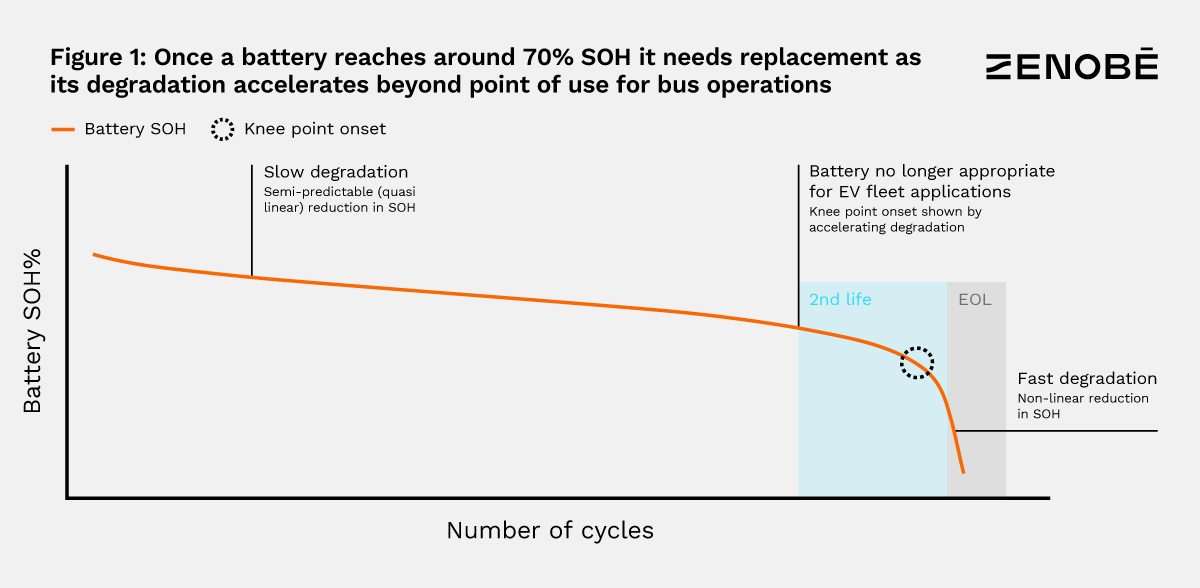

State of health (SOH) – the amount of energy stored by a battery compared to its day one capacity – is the most used measure of degradation and will be referenced throughout this article. In the bus sector, most agree that a battery below 70% SOH will need to be replaced. Therefore, under expected degradation rates, the battery will need to be replaced at least once in a vehicle’s life.

A worked example

For the purposes of this article, we will be returning to the same worked example from our first Switched On, demonstrating the effect of degradation on a 450kWh electric bus battery that costs £150,000 and travels a minimum of 150 miles per day.

It is also worth noting the relatively short time that electric buses have been on the roads in the UK, which limits the available data on battery degradation. Therefore, we will be referencing examples from controlled lab tests and our own internal analysis from the fleet that we currently support.

Battery degradation is largely linear across a wide range of SOH. Some time after degrading past 70% SOH, replacement is usually required as the rate of battery degradation begins to accelerate, eventually reaching the ‘knee point’ where we see a marked change in the degradation rate – as highlighted in the chart below. As the battery degrades faster, the vehicle range will rapidly reduce and the battery will not be usable for its initial purpose – ultimately a vehicle battery will be replaced before this point. Understanding the key milestones in a battery’s are crucial for fleet planning and ensuring operational requirements will continue to be met.

What accelerates degradation and how can it be managed?

There are two aspects that drive battery degradation: Calendar ageing, and battery usage. Without the ability to manage time, operators need to focus on how the battery is used to minimise degradation. The key factors that affect degradation are:

- Energy throughput of the battery

- Depth of charge and discharge – operating range of the battery

- Rate of charge – relating to the power of the charge

- Temperature of the battery.

By looking at these key factors, operators can implement strategies to maximise the useful life of the vehicle batteries and extend the horizon for replacement. We have selected three focus areas where operators can take practical steps to minimise degradation now, and plan for future operation.

Route allocation

By cycling vehicles across different routes of varying service lengths and topographies, operators can ensure that vehicle batteries degrade evenly across the fleet.

Zenobē’s in-house modelling has looked at the impact of repeatedly running vehicles on the same routes each day against cycling them to ensure that they all complete a similar number of miles. The careful management of route allocation can provide the highest likelihood of requiring a single battery replacement during the vehicle’s useful life.

As part of the work to model the cycling of routes, Zenobē has been able to show operators how they can delay replacement of the first battery in a fleet of 50 double-deck vehicles by up to three years.

Additionally, high-powered charging can increase the degradation of a battery, but with vehicle charging windows and grid capacity often limited, many operators do not have a choice. Route allocation is a key tool for ensuring that individual vehicles are not repeatedly charged at an ultra-fast rate.

Depth of discharge

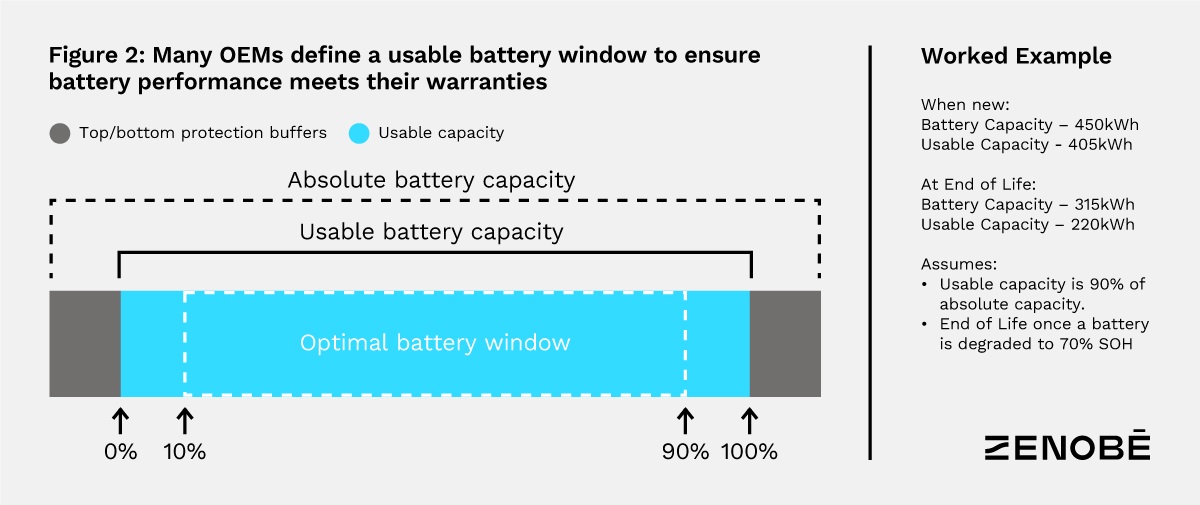

By operating a vehicle outside of its nominal voltage range – the target voltage the battery should be used at – the degradation of the battery will increase. The nominal voltage range of a battery can simply be thought of in terms of the battery’s SOC, with batteries degrading the least when operated between 10-90% SOC.

To help operators remain in this range, many OEMs place limits on the available battery capacity under its warranty terms, as shown by the graph below. In practice, this means that operators cannot access the full capacity of their battery – only the useable capacity.

In addition to this buffer, operators can influence the depth of discharge of their battery by selecting vehicles based on route requirements.

This can ensure that even once the battery has degraded, it will not need to be discharged beyond 10% to run the route. As a bonus, batteries are most efficient when used between 10-90% SOC, meaning that energy losses and electricity bills should be lower.

In some cases, a 90% charged battery is sufficient to comfortably complete a route. For now, many operators still want to charge to 100% to avoid range anxiety and minimise any operational risk. On top of that, most batteries still need to be charged to 100% to ensure that cells are balanced and maintain their performance.

However, looking forward – as operators become more comfortable with electric vehicles and as battery management systems are updated – we expect smart strategies to charge vehicles to less than 100% to be implemented.

Minimise throughput

Electric vehicle drivers themselves can both positively and negatively influence degradation of the battery. Harsh acceleration and braking reduce the vehicle’s efficiency when driving, increasing energy throughput in the battery and so degradation.

Key to managing energy throughput is a software platform that reports performance data. Zenobē’s software has shown that driver training and performance tracking can lead to a 20% improvement in vehicle efficiency through better driving styles. Over a year, this can reduce throughput and depth of discharge significantly, both slowing degradation and saving on energy costs.

The implication of battery degradation on TCO – an opportunity

Understanding degradation Is vital for keeping electric bus TCO low, as it allows for:

- Minimising the need for battery replacements and reducing the associated costs

- Increasing the residual value of the end-of-life batteries, thus decreasing the first-life cost.

Minimising replacements

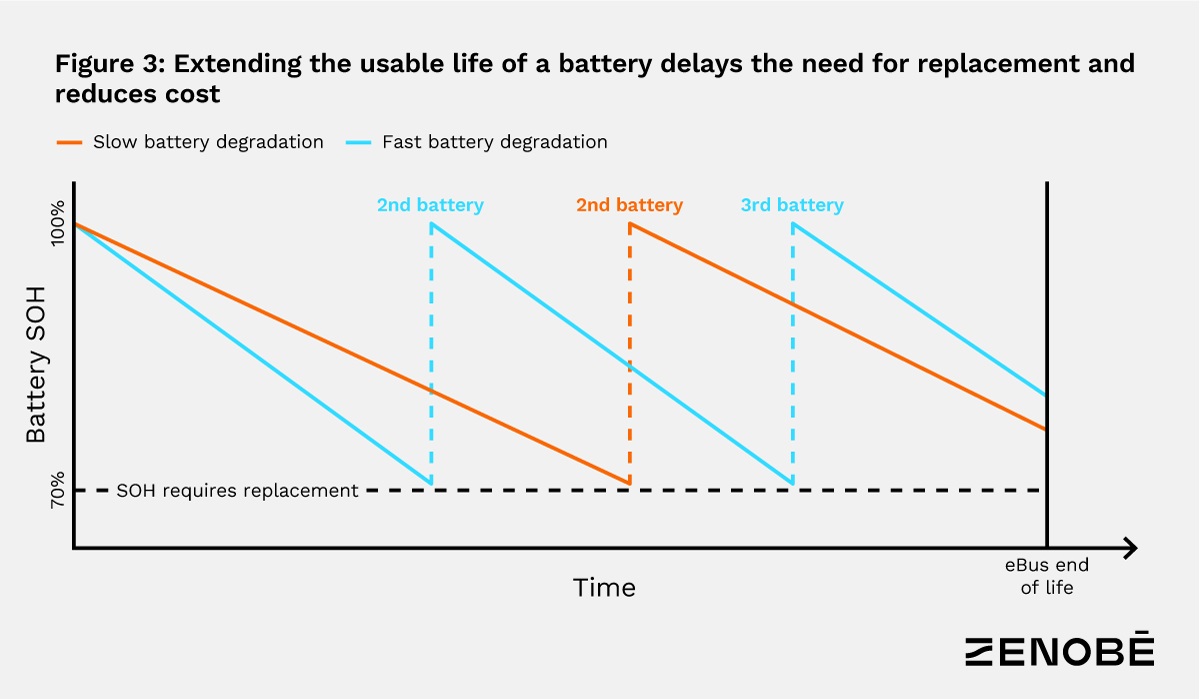

With fewer moving parts and lower vibrations, we may see electric buses on the road for up to 20 years. Current battery warranties stand at around eight years, and so there Is an expectation that two battery replacements may be required.

Operators that manage degradation can slow it down, minimising replacements and potentially halving the capital outlay, as shown below.

Increasing the residual value

The TCO for an electric bus Is also Influenced by the residual value that can be assigned to batteries as they are removed and replaced.

Each electric bus battery is made up of packs, with each pack made up of several modules. Based on extensive conversations with the battery recycling industry, we estimate that 70-80% of modules will have adequate SOH for new, less intensive applications, or as we call it at Zenobē, a second life.

Many operators now choose to work with specialist lessors like Zenobē, which will take ownership of battery risk through a battery-as-a-service model or ‘battery managed service’. Paid as a fixed monthly rental over the life of the electric bus, this service removes the risk of replacement and exposure to battery markets.

Moreover, with a second life residual value, this fee can be reduced. With data to understand how the battery has been used, specialist lessors like Zenobē can forecast how it will perform in second-life applications, boosting their value and further reducing fees for operators.

The key takeaways

Managing degradation Is crucial to reducing electric TCO. As the industry shifts to a new way of operating, considerable strategies to minimise degradation now will enable operators to avoid costly, and potentially unnecessary, battery replacements in the future.

In our next article, we will share with routeone readers a review of charging infrastructure and how to make futureproofed decisions that will reduce the lifetime costs of your fleet.