From tools and seat coverings to electrics, an operator has plenty to keep in mind when caring for its vehicles. We spoke to some of the businesses lending a helping hand

Refurbishment is apparently booming, as noted a few months ago by Alexander Dennis, which says operators are looking to make vehicles last longer. In addition, the trend for sustainability and cutting costs in the long run due to small profit margins mean engine maintenance is similarly important. We look at some diverse solutions for keeping your coach or bus in tip-top condition for longer.

Tools for the job

The precious commodity of time is at stake in the coach and bus workshop. Laser Tools has a variety of tools to assist in that regard. It supplies specialist workshop tools for servicing and repairing a wide range of commercial vehicles, including coaches and buses.

One of the most popular tools in its range is a slotted bearing bush removal and installation tool. The road springs of many chassis are fitted with slotted bearing bushes which are constructed with a split steel outer casing bonded to the rubber inner section. During safety inspections, the condition of these bushes is carefully checked and, if any wear is detected, the bushes must be replaced. Removal and subsequent replacement of this type of bush is impossible without the correct equipment. This comprehensive kit uses a compact 12-tonne hydraulic ram — to be used with your workshop hydraulic pump — that allows the operator to swiftly complete this awkward job, which is usually carried out in a limited-access environment.

The company can also help when it comes to wheel bearing servicing. The first task is to remove the bearing lock nut and, for that job, Laser Tools has an adjustable wheel bearing lock nut tool which is specifically designed and sized for large commercial use. The jaws of the clamp are easily adjustable to the required size, then locked into place. It is used for removing and replacing the likes of wheel bearing retaining nuts, castellated retaining nuts, threaded bearing housing caps and grease caps.

Electric specialists

Electrical systems and components are becoming ever more central

to coaches and buses, with engineers and operators increasingly having to call on specialists such as Bus Electrical, which feels its wide range of services makes it stand out. Founder and Director Adam Fairclough says: “Some businesses will just do the fault-finding diagnostics; some will just do installations. We do both those things, which I think is unusual.”

He adds: “Day-to-day, we do vehicle fault-finding, diagnostics and repairs on electrical systems from the engine and gearbox up to the ramp and doors and everything in between. We also do installation and maintenance of your extras, like LED lighting, USB charging, wi-fi and CCTV.”

Bus Electrical has been busy in particular with its newly developed LED lighting, which can replace the fluorescent tubes which are proposed to be banned by the government this year. According to Adam, the new lights are designed to be so easy to fit that the operators can do so themselves using existing wiring. “They instantly refresh the look of a bus on the inside,” says Adam. “From a passenger point of view, you feel like you’re in a more modern space straight away from the lighting.” Adam says the whole LED light unit is cheaper to replace than the inverters which drive fluorescent lamps.

Zero-emissions buses are another growing area for Bus Electrical, with Adam saying: “Electric buses are starting to come off warranties, so we are starting to get more involved with them.”

Lasting fabrics

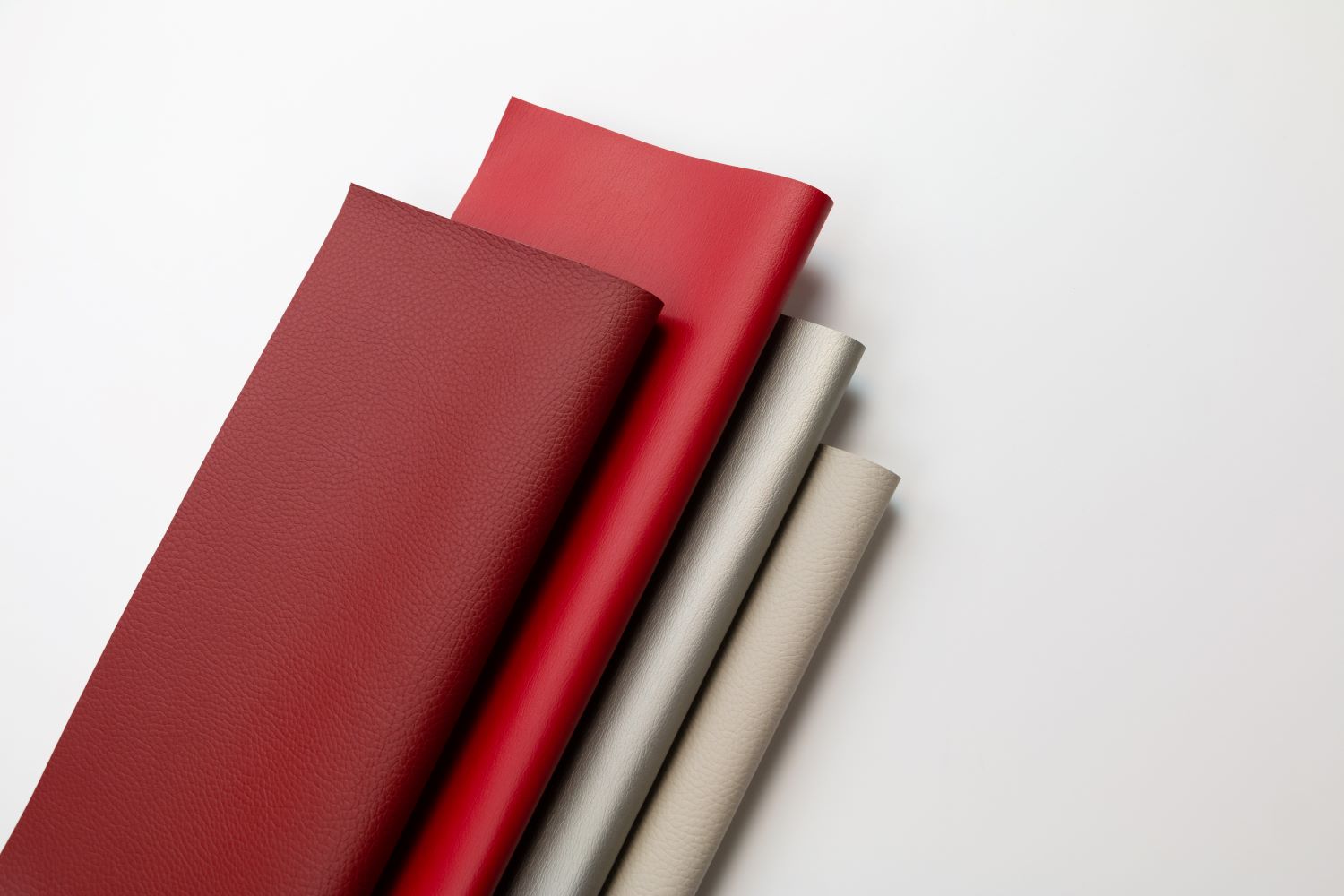

Just as the latest battery-electric developments are having a significant effect on vehicles, the newest fabric technology is creating a better look for the customer-facing fittings.

Ultrafabrics’ high-performance materials are designed to provide passengers with a luxurious, comfortable and safe environment that can be easily cleaned and cared for and last for years.

All Ultrafabrics’ collections are manufactured with the proprietary process Takumi technology. Taking its meaning from the Japanese word for “artisan”, the process is one unified system designed for lasting strength and comfort, incorporating inherent climate control technology and enhancing passenger experience.

European Sales Director Richard Field says: “Our portfolio is engineered using the highest-quality ingredients, which translates to high performance and longevity in the field. Thanks to our superior polycarbonate-based polyurethane resins, the majority of Ultrafabrics’ materials test to 16 weeks for hydrolysis resistance — head and shoulders above the industry standards of five weeks.”

Ultrafabrics is proud of its contribution to sustainability in the industry. It has made the commitment that, by 2025, all its branded products sold to furniture, healthcare, recreational vehicle, marine, aviation, and accessories markets will be at least 50% rapidly renewable and/or recycled materials.

“At Ultrafabrics, we’re shaping the future of high-tech materials, where sustainability is built-in,” says Richard. “Beauty, performance, longevity, sustainability – there’s no need to compromise. Material innovation has never been more important. As we shift away from virgin synthetic and finite resources, it is essential that the replacements are scalable, plentiful, and derived from rapidly renewable or recycled sources. These new materials must also withstand the performance requirements of diverse applications.”

Working safely

Using safe pits in the workshop is an essential for health and safety reasons and Premier Pits knows a thing or two about that, having been manufacturing and installing pits for 40 years. The company’s range includes inspection, maintenance, rail, and washdown pits, all supported by various pit accessories and health and safety equipment. Under-chassis, wash pits and ramps are also available, while Premier Pits is the UK distributer for BrakeMate, which eliminates heavy lifting during the brake disc-change process.

Marketing Manager Matt Dilley says: “From the first point of contact to the completion of the job, Premier Pits offers a complete package. Advice is given on the type of pit to install, along with the modifications and accessories required for working on specific vehicles. Our skilled and experienced design engineers use the latest CAD facilities to provide design support to architects, structural engineers, and contractors alike.

“Although all pits are built around standard basic formats, they can be tailored to suit individual customer needs, thereby making available an endless range of combinations. Once delivered to the site, the pits are installed by one of our own teams of skilled and experienced fitters.”

The company has recently introduced its “Premier Hinged Cover”, which is a new pit-fall restraint to protect staff from falls while maximising the working space. It believes such pit covers are becoming ever more popular due to health and safety regulations. Premier Pits Managing Director Mel Burrell says: “There is no requirement for a storage cassette, meaning that a pit of any length can be covered with minimal working space lost. This solution offers a quick and easy way to protect staff from accidents in the workshop.”