An area of the industry that stands on the cusp of a zero-emission shift is minicoach and minibus, believes EVM. The manufacturer has already made progress with battery-electric examples of its accessible products in two size classes, with Sales and Marketing Director Peter Flynn predicting that orders in that segment will steadily ramp up as the benefits of zero-emission gain traction.

Battery-electric is also firmly on the radar for EVM’s established minicoach and midicoach range. Peter notes that the accessible products referenced above – the low-floor e-Cityline and lift-equipped, high-floor e-Elegance, both built using the Mercedes-Benz Sprinter, and the larger Composite Mobility family member mounted on an Iveco Daily – were prioritised because of demand, but deployment of the same driveline in small coaches is approaching.

Indeed, EVM has already spoken to customers in the coach industry about how its Sprinter-based minicoaches in battery-electric format could fit their fleets. One such discussion late in 2022 was particularly productive thanks to an existing element of zero-emission experience for the operator concerned, says Peter.

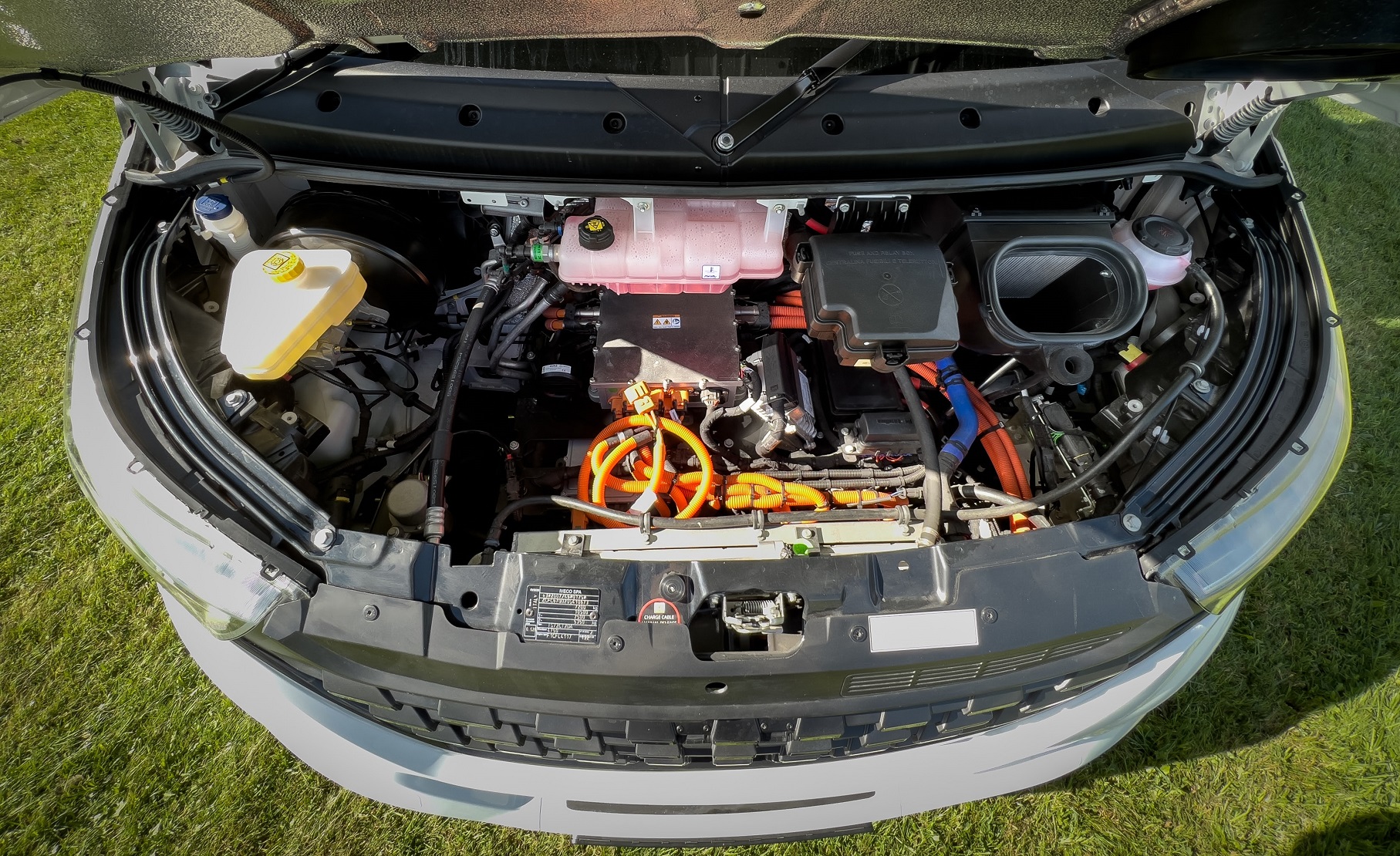

“This is what the Elinta Motors driveline we use suits; it fits into the engine bay, with one of its battery modules outside. In a low-floor vehicle that module goes at the rear, but a high-floor layout means that it goes at the front, leaving space for our drop boot or a lift and allowing a well-packaged approach.”

EVM battery-electric driveline options well-developed

The Elinta package is suited to all EVM Daily- and Sprinter-based zero-emission models, although the OEM battery-electric offering from Iveco will soon be added as an option. Differences exist between each supplier’s solutions, and discussion with the customer will be required to decide upon the most appropriate of the two in Iveco vehicles, EVM expects.

Elinta is based in Lithuania, and it installs 115kW/h of battery storage as part of its product. Because the energy capacity is lower than in full-size battery-electric coaches and buses, so too is the required infrastructure need. That gives significant flexibility for electric minicoaches and minibuses, Peter believes.

“Charging infrastructure does not need to be the big expense people expect,” he says. “As an example, we fitted a 22kW AC unit at our previous premises. It cost around £1,000, with installation a further £600.” Allowing for residual charge remaining in the batteries, such an application could charge a minicoach or minibus in four hours or less.

Where battery-electric minibuses have been deployed already, they are performing well. That is evident for Denbighshire County Council, which has an e-Cityline working a mix of fixed-route and demand responsive services.

Supply chain disruption at the OEM had slowed the pace of the rollout of battery-electric Sprinters, but Peter says that those difficulties have eased and EVM is in a good place to build on its existing base. It expects to deliver at least 50 zero-emission vehicles this year, utilising both the Daily and Sprinter as bases.

Battery-electric charging scope a major plus, says EVM

In a further positive, battery-electric minibuses by dint of their size can use public charging points. Indeed, EVM has done that many times when moving such vehicles around the country. A 100kW charger could be expected to replenish one of its models in no more than an hour.

“That is barely time to have lunch,” Peter notes. At present, the Elinta driveline delivers a range of around 200 miles in an accessible Sprinter-based model; a minicoach would be expected to be similar, as additional weight in higher specification trim would largely be mitigated in other areas. A rapid recharge while the driver has a break would open the door to significant daily mileage possibilities, while relying on publicly accessible infrastructure.

Alternatively, if existing chargers for heavy battery-electric vehicles are part of the operator’s strategy, the Elinta driveline can be used with them. Presently its power draw is limited to 120kW, but later the package will be compatible with a maximum 150kW supply.

That gives a rapid replenishment and would allow battery-electric minicoaches and minibuses to use bus depot chargers in a way like that already observed by a van operator in Glasgow.

Supporting zero-emission vehicles also a focus

While Dailys with Iveco’s own battery-electric driveline are ex-factory in that format, the Elinta package is purchased by EVM and installed into a new Daily or Sprinter. Elinta has devoted significant time to the integration process to ensure that its product works correctly with the vehicle’s CAN bus. The driveline is connected in real time, and that brings a major benefit to maintenance and support.

“We can see every battery-electric vehicle’s location and its state of charge, and if any issues are present,” Peter says. “In the latter case, we can immediately interrogate the vehicle. We can pull the data logs; if the matter is related to charging, we can inform the operator that perhaps it was not plugged in correctly, for example.

“If it was something else, the aftersales team can take a closer look. Doing that at the time of diagnosis is much faster and much simpler.”

Such an approach forms part of the total cost of ownership consideration, EVM believes. A zero-emission vehicle is more expensive upfront than a diesel, and in multiple sectors that has been highlighted as a potential blocker. But purchase price should be looked at as one part of the equation, and particularly where the Composite Mobility product is considered, Peter continues.

In that case, the body is both significantly lighter than a conventional model, and it has a much longer potential lifespan. EVM has claimed that the composite structure will last for up to 40 years, and that in an extreme case, it could be removed from one chassis and mounted on another.

Regardless of the construction method or the battery-electric model chosen, more should be considered than merely the upfront outlay, Peter says. “It’s the saving on fuel and the saving on servicing,” he continues. “There is also potentially a lifetime implication with the lack of vibration from an engine.”

Ongoing investment being made behind the scenes

While vehicles are the hot ticket for zero-emission, support factors heavily into their success. The Elinta driveline’s connectivity helps that, but EVM has also put human resource into backing its battery-electric line-up.

“We have nut-and-bolt reviewed every step of our aftersales process,” Peter explains. “That includes new premises near Horsham, but it also involves people and the structure of how support is delivered.” What is there now is scalable in preparation for what EVM believes will be a major uplift in battery-electric sales over coming years.

Central to backup are Aftersales Manager Ian Edgerton and Customer and Network Support Manager Andy Mageer. EVM accepts that not every buyer would wish to bring a vehicle back to its West Sussex base if attention is required, and thus part of Andy’s responsibilities is ensuring that the required level of backup is present at service partners elsewhere. The customer support mechanism has been upgraded at the same time to reflect the bulking up of overall aftersales provision.

Electric efficiency relies on hardware and software combination

Although the Elinta driveline has performed well thus far, further improvements are expected beyond those already deployed. Software upgrades are at the root of most uplifts, but hardware will also change at around the middle of this year. Battery container weight has already reduced, while battery voltage is to increase, and a change will be made to the inverters. The latter will allow faster throughput of power in both directions, indicating that regeneration performance will benefit.

Operators that have sampled the small battery-electric products like them. “We see a lot of gentle head-nodding from those parties when they return,” Peter continues.

“There is an acceptance that the product is here now. It’s not a prototype; there are battery-electric minibuses available that will deliver the required mileage and give a very pleasant driver and passenger experience. They are reliable and we can support them more quickly than ever, and there is likely to be a longer lifespan – all while delivering zero emissions.”

That messaging tells EVM that interest in battery-electric minibuses and minicoaches is growing, and rapidly. Zemo Partnership has already noted that those vehicles are ideally suited to shorter-distance duties; with the current pace of driveline development, they are also quickly approaching a form suitable for longer-distance applications.