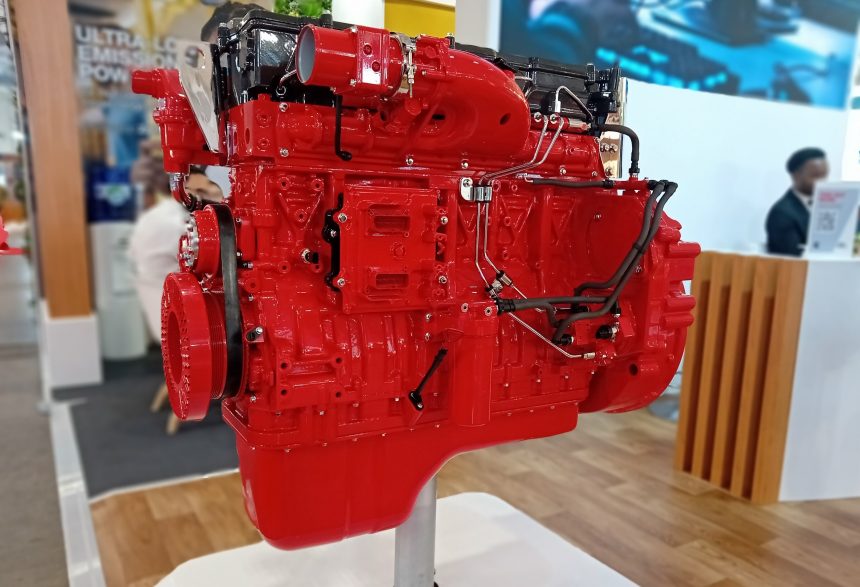

Cummins has revealed examples of a three-strong engine platform that will be Euro 7 ready as part of work that leaves the business aiming to be a “power expert.”

The 10-litre X10 and 6.7-litre B6.7 display a versatile approach to next-generation engines. Alongside a 15-litre X15, the range will employ common blocks but different heads to permit the use of CNG, diesel, or hydrogen combustion, respectively. While the X10 exhibited at Busworld was a diesel example, the smaller unit adjacent was the hydrogen fuelled B6.7H.

Such an approach represents Cummins’ belief that “there will not be one solution in the future,” says Marketing Communications Director Steve Nendick. It sits alongside work on battery and hydrogen fuel cell power.

He notes that Cummins expects each engine model to occupy the same amount of chassis space regardless of its fuel type, simplifying fitment for vehicle manufacturers. Outputs on diesel and hydrogen are similar, Mr Nendick continues. The existing Euro VI diesel B6.7 can produce 320bhp, while the B6.7H develops 290bhp.

Although the UK government in 2022 indicated that it does not consider hydrogen combustion to be zero-emission, it is now understood that a change of heart on that policy may be in hand.

“The hydrogen engine cylinder head has been designed specifically, and it is not an adaption of a diesel head,” he explains. Hydrogen combusts via spark ignition and Cummins notes that the B6.7H well suits midicoaches in the 9-10m category.

As also highlighted by another engine OEM, uncertainty currently clouds the introduction of Euro 7. Questions have been raised over the specific emission standards required, while a possible two-year delay in implementation from the originally expected 2027 date has also been raised.

Using the Euro 7-ready X10 as an example, Mr Nendick says that the unit will be able to satisfy the standards when they are formally laid down. To do that, it will employ variable valve timing and double overhead camshafts (neither of which are mandatory to reach Euro VI) and a new aftertreatment unit. The combustion recipe has also been enhanced and ‘dual dose’ aftertreatment will be employed.

There is no expectation that Euro 7 units will run hotter than Euro VI engines. They will be able to consume HVO, as is currently the case, and the X10 will be compatible with B100, or 100% blend, biodiesel. The same characteristic of low-down torque that Cummins engines are known for will continue, he adds, with the X10 peaking at 2,300Nm and 45obhp.

While Cummins is currently not active in the market for new full-size coaches in the UK, reluctance among some vertically-integrated vehicle OEMs to develop Euro 7 across their current engine ranges may help it regain ground. Mr Nendick says that the X10 will suit coaches well and that early discussions with a number of manufacturers have taken place.